DESCRIPTION:

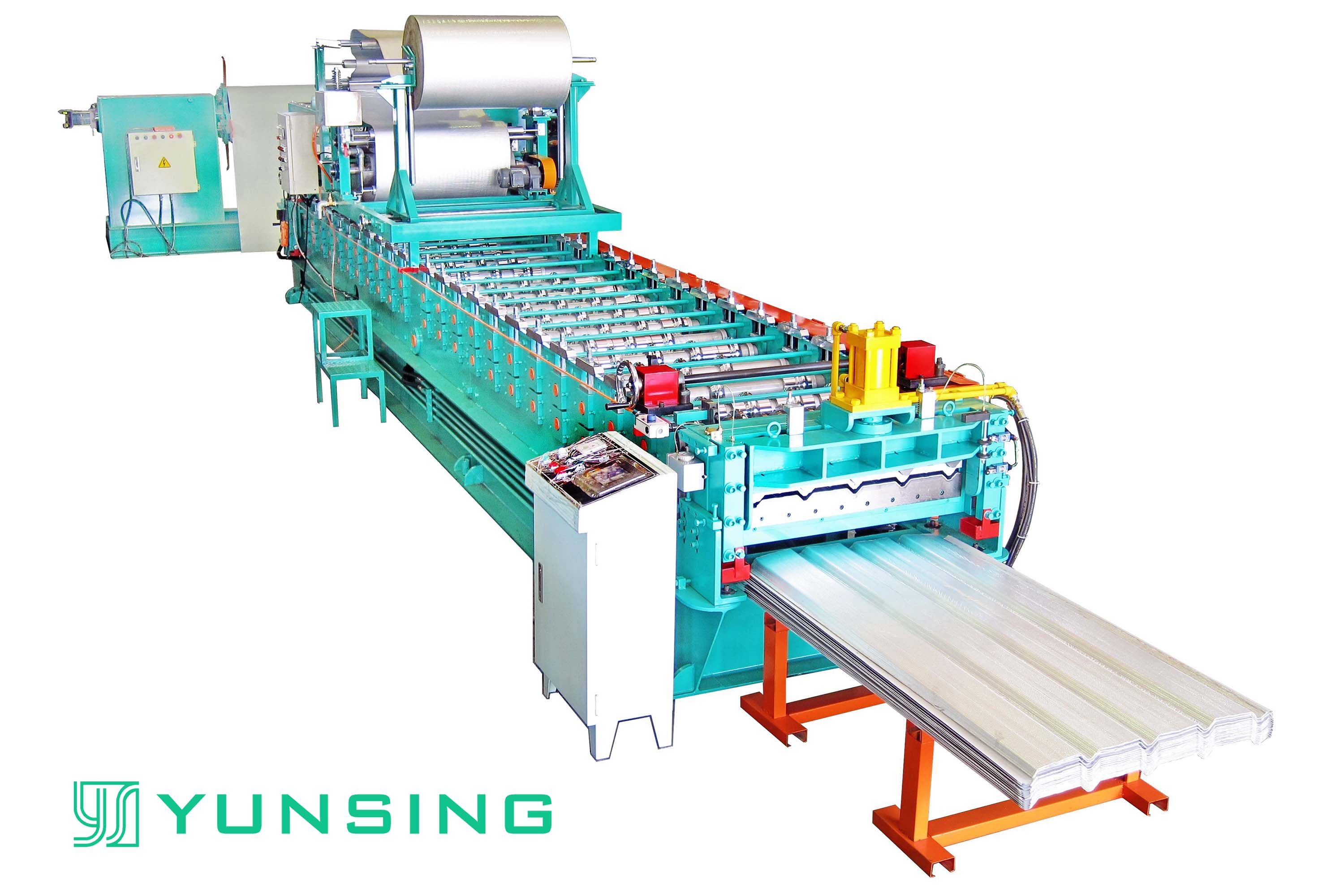

Laminated PE Foam Roll Forming Machine

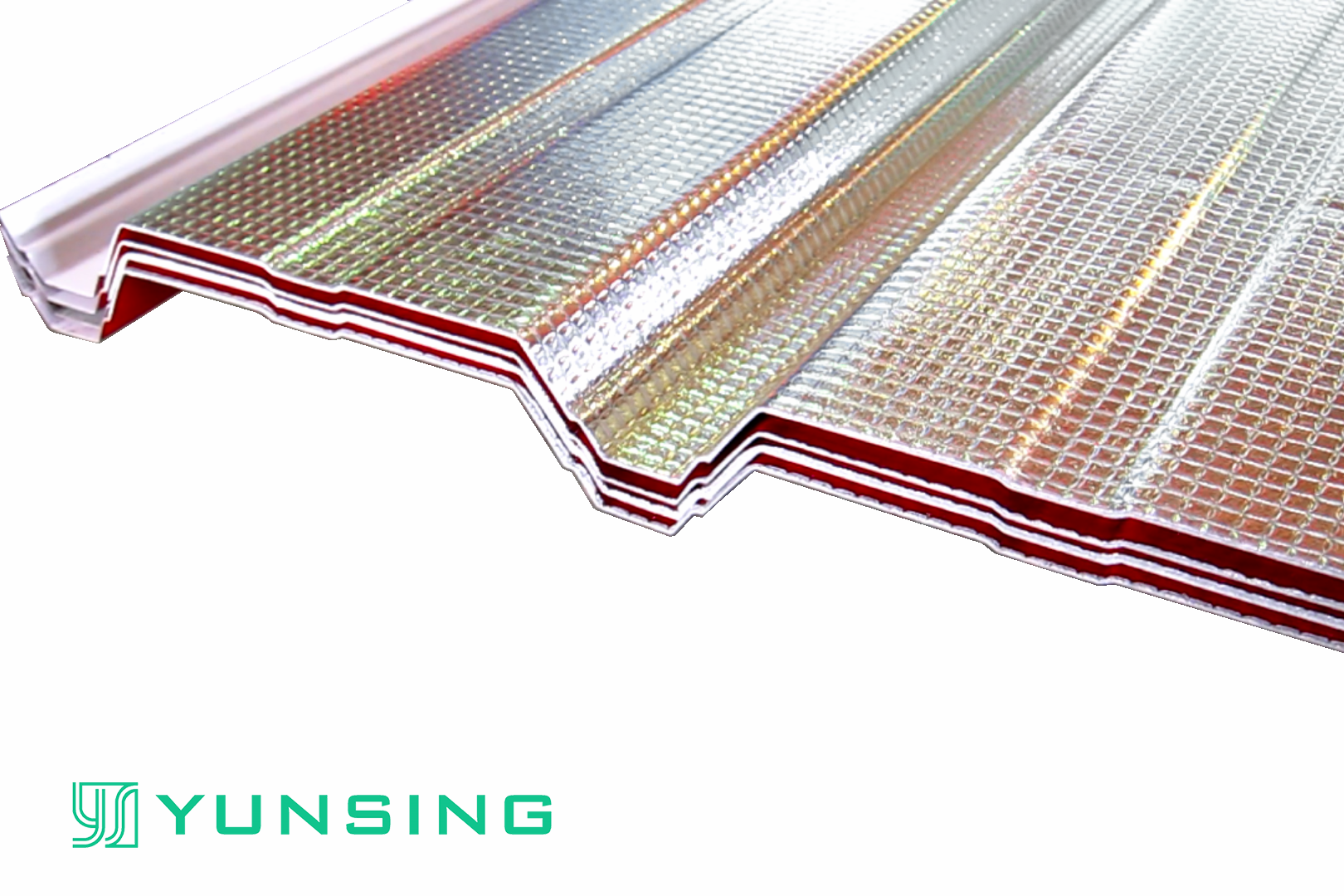

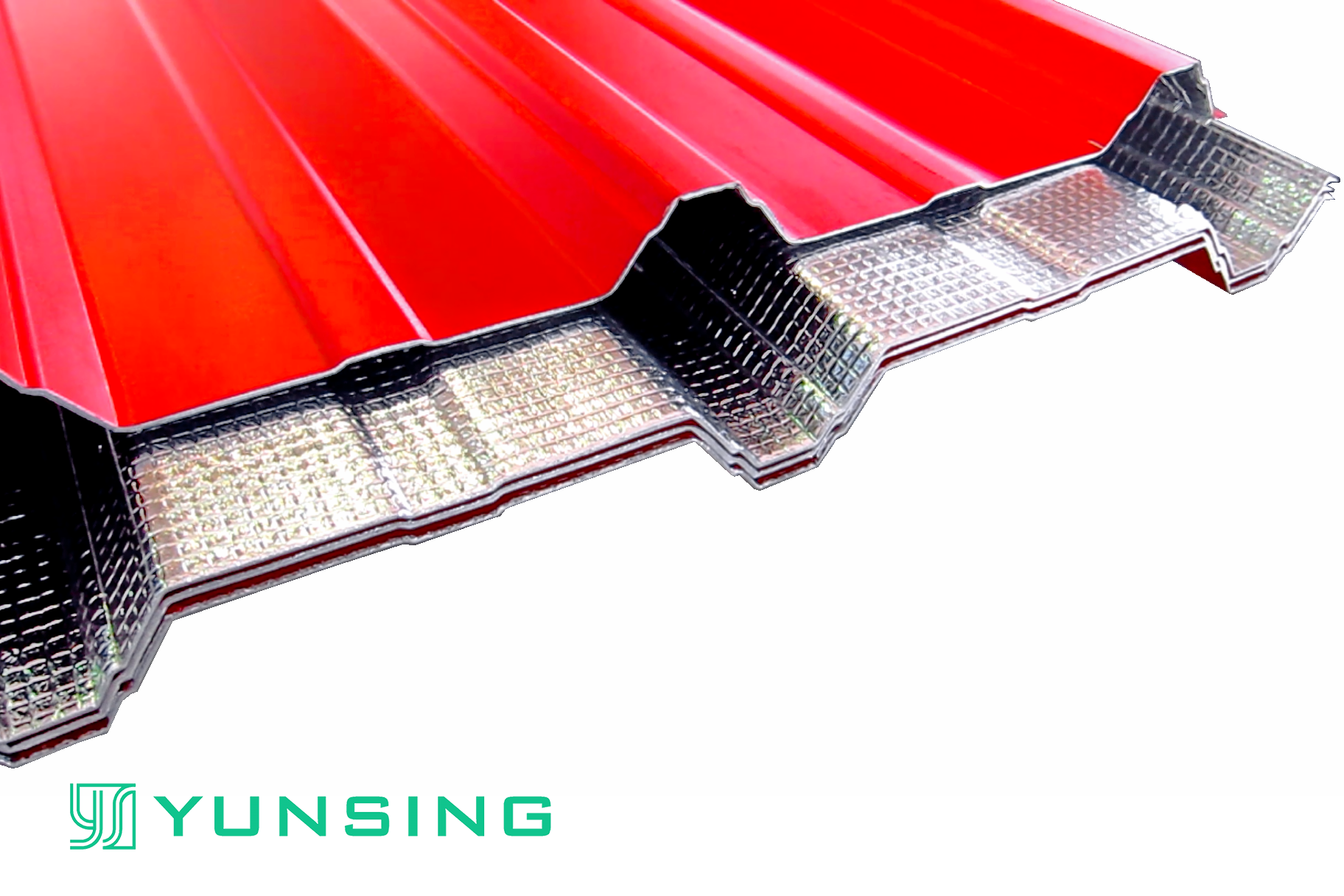

Under global warming challenge, Laminated PE Foam becomes a smart and economical product on Weather-Resistance performance.

Yunsing design an easy Laminated PE Foam system which available for various profiles, this optimized production line brings extra profit on all regular Roofing products.

YS-900 serious including Roofing, Wall Cladding available for both Coated Coil (PPGI/PPGL) and Galvanized Coil (GI/GL).

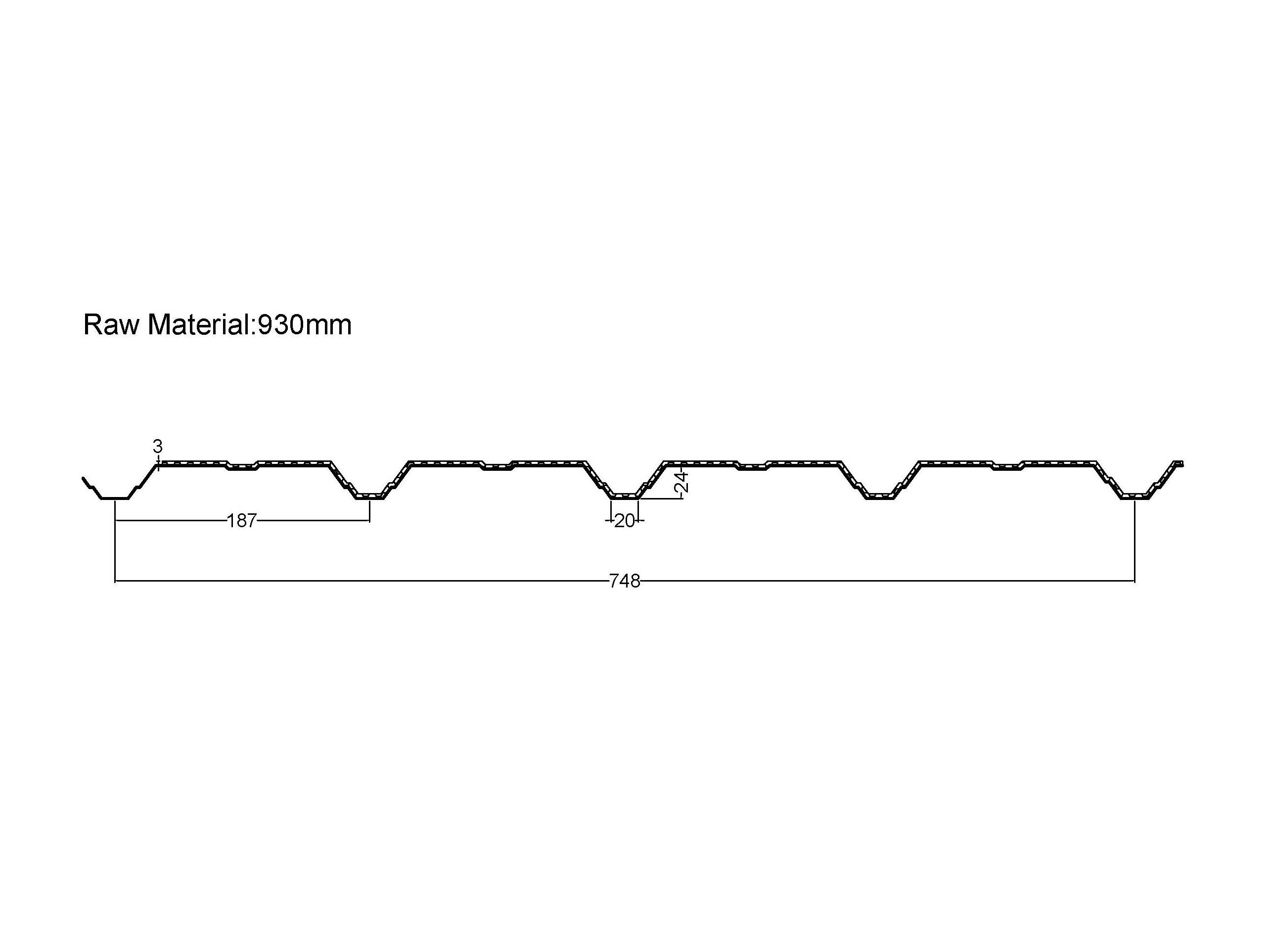

PROFILE-DRAWING:

Laminated PE Foam Roll Forming Machine

SPECIFICATION:

Laminated PE Foam Roll Forming Machine

Specifications

o Thickness of material : 0.3 mm ~ 0.8 mm

o Forming speed: 15~25 m/min.

o Hydraulic driving and cutting system.

o Hard chrome coated rollers.

Advantages

o Customized profile and suggestions.

o Material handling solutions.

o Anti-capillary grooves, Embossing, Logo Marking.

o Full safety protection with cover guard, emergency switches, mistake proofing program.

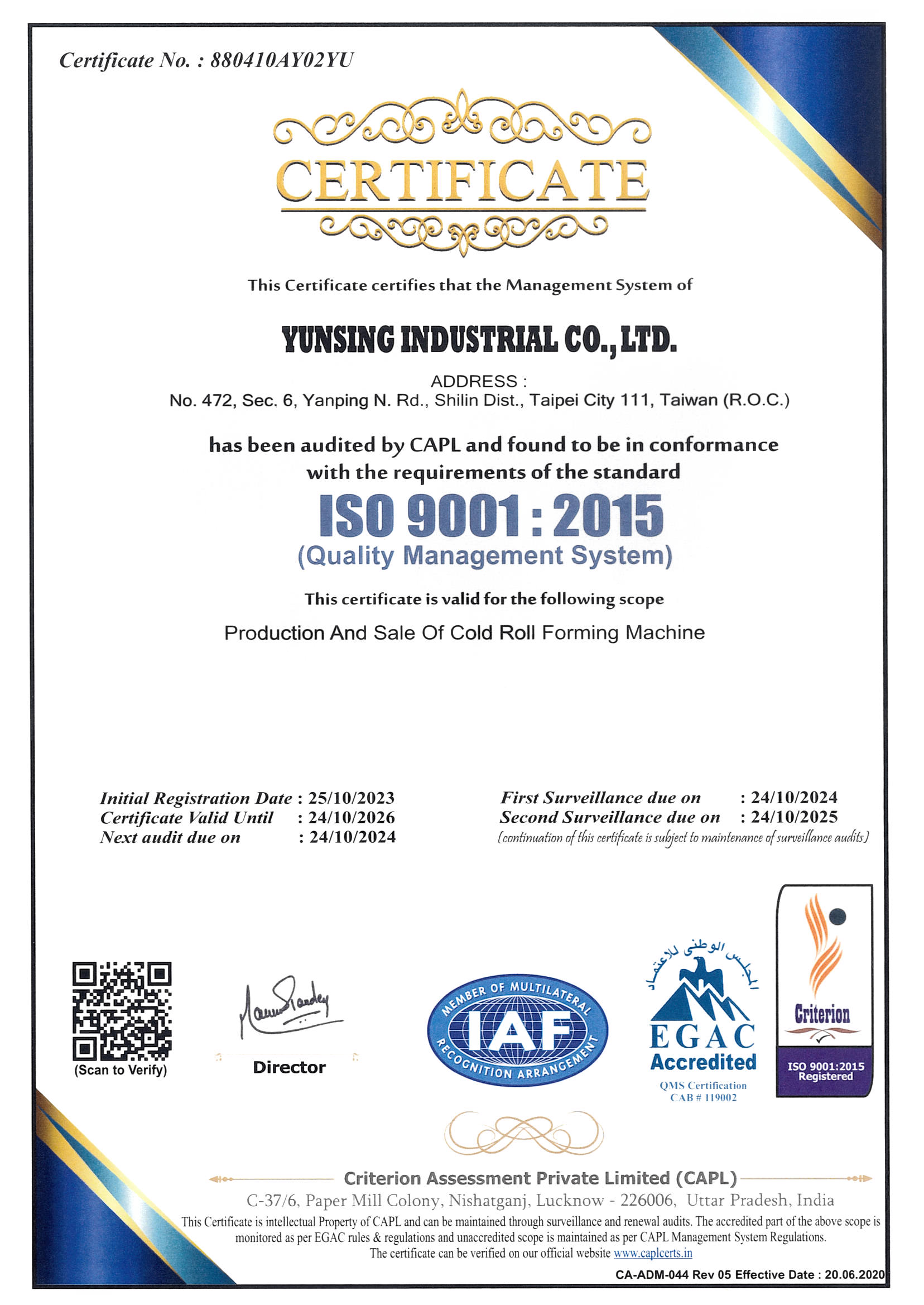

YUNSING INDUSTRIAL